Filling and priming of HP 970, HP 971 inkjet cartridges connected to CISS

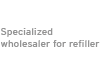

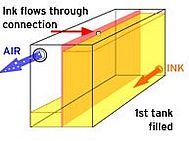

The inside of the HP 970 and HP 971 versions is split by a deviding wall into two tank sections. At the XL versions both sections are connected to each other by a connection hole in the lower part of that devider.

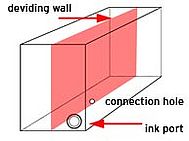

HP 970 XL and HP 971 XL have both chambers filled with pigmented ink when arriving from HP´s factory. The connection to the CISS is made in the upper right corner of the rear wall opposite the wall equipped with the ink port.

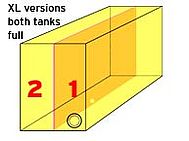

For filling and removing the air the cartridges are positioned on their upper side. Now the ink port and the connection hole in the deviding wall are the highest points. The negative pressure created by extracting air from the cartridge pulls ink from the external tank into the tubes and then into the tank section connected to the tube. The ink level in that tank section is rising up until reaching the connection hole in the deviding wall. Through that opening the ink also flows into the second section.

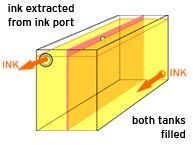

There is the same effect in the ink port´s tank section as in the chamber with the connection to the CISS tube. Here the ink port is the upper point and the ink level rises until it reaches the ink port. When the level has come up that far the content of the syringe used to extract the air changes from a foamy mixture of air and ink to clear ink. Then You know that both ink tank sections are as full as possible.

The procedure has to be done for each cartridge connected to the CISS. Primed and fully filled the complete system is ready for use in a HP Officejet Pro working with HP 970, HP 971 inkjet cartridges.

QU-Fill™ PROFI for HP® 932, 950, 953, 970, 980 and Primera spring valve cartridges, brass

QU-Fill™ PROFI for HP® 932, 950, 953, 970, 980 and Primera spring valve cartridges, brass

HP 970, 971 chips for black, cyan, magenta and yellow ink cartridges

HP 970, 971 chips for black, cyan, magenta and yellow ink cartridges

Refill ink compatible for HP 970 black pigmented

Refill ink compatible for HP 970 black pigmented

Refill ink compatible for HP 971 cyan pigmented

Refill ink compatible for HP 971 cyan pigmented